Contact parameters

| Contact form |

1Z,1H,1D |

| Contact load |

16A |

| Maximum switching voltage |

240VAC 16A

28VDC 16A |

| Contact material |

Silver alloy |

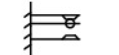

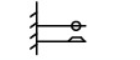

Description of contact forms

| Name |

Domestic code |

International code |

Structural form |

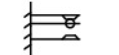

| Conversion type |

Z |

C |

|

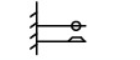

| Normally open |

H |

A |

|

| Normally closed |

D |

B |

|

Switching type:

The center is a moving contact, coil is not energized, the moving contact and one of the static contact is disconnected and the other one is closed, after the coil is energized, the moving contact will move, so that the original disconnected into a closed state, the original closed into a disconnected state, to achieve the purpose of conversion.

Normally open type:

The contacts are open when the coil is not energized and closed when energized.

Normally closed type:

The contacts are closed when the coil is not energized, and the contacts are closed when energized.

Operating Coils

| Rated voltage V |

DC12V |

DC24V |

DC110V |

DC220V |

| Rated current(+10%)mA |

125 |

62.5 |

13.6 |

6.8 |

| Coil resistance(+10%)Ω |

96 |

360 |

6800 |

27500 |

| Rated power consumption W |

0.9W |

| Pick-up voltage(max)V |

Less than 75% |

| Drop-out voltage (min) V |

10% or more |

| Allowable voltage(max) V |

Rated voltage ×110% |

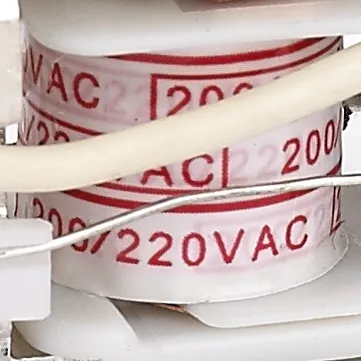

| Rated voltage V |

AC12V |

AC24V |

AC110V |

AC220V |

| Rated current(+10%)mA |

208 |

104 |

22.7 |

11.3 |

| Coil resistance(+10%)Ω |

20 |

80 |

1680 |

6700 |

| Rated power consumption W |

1.2VA |

| Pick-up voltage(max)V |

Less than 80% |

| Drop-out voltage (min) V |

30% or more |

| Allowable voltage(max) V |

Rated voltage ×110% |

Product Technical Parameters

| Contact resistance |

≤100mΩ |

| Electrical life |

≥10⁵ times |

| Mechanical life |

≥107 times |

| Coil voltage |

DC: 6-220V AC: 6-380V |

| Suction time |

≤15ms |

| Release time |

≤15ms |

| Between the same pole contacts |

1000VAC/1min(Leakage current 1mA) |

| Between opposite pole contacts |

1200VAC/1min(Leakage current 1mA) |

| Between contact and coil |

1500VAC/1min(Leakage current 1mA) |

| Insulation resistance |

≥500MΩ(500VDC) |

| Ambient temperature |

-25°C ~ +55°C |

| Ambient humidity |

35% ~ 80%RH |

| Atmospheric pressure |

86 ~ 106KPa |

| Impact resistance |

10G (Sine wave half pulse: 11ms) |

| Vibration resistance |

10-55Hz (Double amplitude: 1.5mm) |

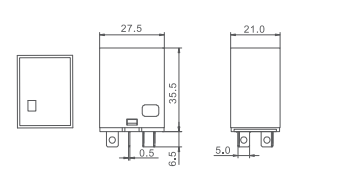

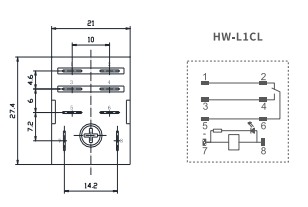

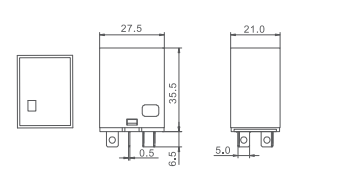

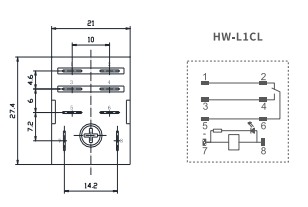

| Dimensions |

27.4 × 21 ×35.4mm |

| Weight |

About 35g |

Product Size and Installation

Selection Guide

Unless otherwise specified, all load currents indicated on the Hangwang relay case are for resistive loads. Under the rated switching voltage, the allowable current of inductive loads should not exceed 30% of the rated resistive loads, the allowable current of motor loads should not exceed 20% of the rated resistive loads, the allowable current of lamp loads should not exceed 10% of the rated resistive loads, and the allowable current of capacitive loads should not exceed 5% of the rated resistive loads. In order to ensure the reliability of the product, it is recommended that the contact load current value should not exceed 60% – 70% of the steady state current value under the rated load of the product.

| Nature of the load |

Inrush current |

| Resistive load |

1 times the steady-state current |

| Sodium lamp load |

1-3 times the steady-state current |

| Mercury-vapor lamp load |

3 times the steady state current |

| Inductive load |

3-5 times the steady-state current |

| Motor load |

3-5 times the steady-state current |

| Voltage load |

3-5 times the steady-state current |

| Incandescent lamp load |

3-5 times the steady-state current |

| Capacitive load |

3-5 times the steady-state current |

Matters needing attention

①Please do not touch the relay terminals and the connected electrical accessories under the energized state, and cut off the power supply when installing, maintaining and troubleshooting the relays (including terminal blocks, sockets and other connected parts). If you need technical support, please contact the service center of Hangwang Electrical Appliances.

②Do not use the relay beyond the rated load. Overloading may cause insulation degradation, contact sticking, poor contact and other malfunctions, and may even cause the relay itself to break and burn out. If you need technical support, please contact Hangwang Electrical Service Center.

③Please avoid dropping the product during storage and use, and do not disassemble the internal components. To avoid damage, burnout and electric shock. If you need technical support, please contact Hangwang Electrical Service Center.

④Do not use it in flammable or explosive gas environment. And avoid using in the place where there is water, steam, melting phenomenon after icing or water droplets falling. If you need technical support, please contact the service center of Hangwang Electrical Appliances.

⑤The rated performance values in the data sheet, if not specified, are the values under the standard test conditions of JIS C5442 (temperature +15°C ~ +35°C, relative humidity 25 ~ 75%, air pressure 86 ~ 106KPa). In addition to the load conditions, the operating environment must also be verified under the same conditions as the actual operating conditions when using the actual equipment. For technical support, please contact the service center.

⑥The coil of relay has polarity (positive and negative poles are marked on the wiring diagram), please check the wiring diagram before connecting the terminals, and then connect the wires correctly, it is strictly prohibited to connect the terminals in reverse, if it is connected incorrectly, it will cause malfunction, abnormal heat and fire. If you need technical support, please contact the service center of Hangwang Electrical Appliances.

⑦Avoid continuously applying voltage to the coil exceeding the maximum switching voltage. If you need technical support, please contact the service center of Hangwang Electrical Appliances.

⑧ For more technical problems, please contact our service center. Tel:155-5873-3666