Intermediate relay is an electromagnetic switch element widely used in automation control systems to isolate and amplify signals. It can convert one signal into multiple output signals to realize complex control logic. Intermediate relay plays a key role in the fields of power, automation control, instrumentation, etc. to ensure the stable operation of the system.

What Is an Intermediate Relay?

An intermediate relay is a type of electromechanical relay mainly used to amplify, isolate, and transmit signals between low-power control inputs and high-power loads.

Unlike power relays that directly control devices like motors or heaters, intermediate relays act as a bridge between controllers and actuators, which is why they are called "intermediate."

Why Use Intermediate Relays?

Industrial users often encounter issues like low output current from PLCs or control boards, voltage mismatches between control and load circuits, the need to create multiple outputs from one control signal, and the requirement for electrical isolation to protect sensitive devices.

Intermediate relays address these challenges by serving as signal isolators, contact multipliers, signal amplifiers, and output converters.

Basic Structure

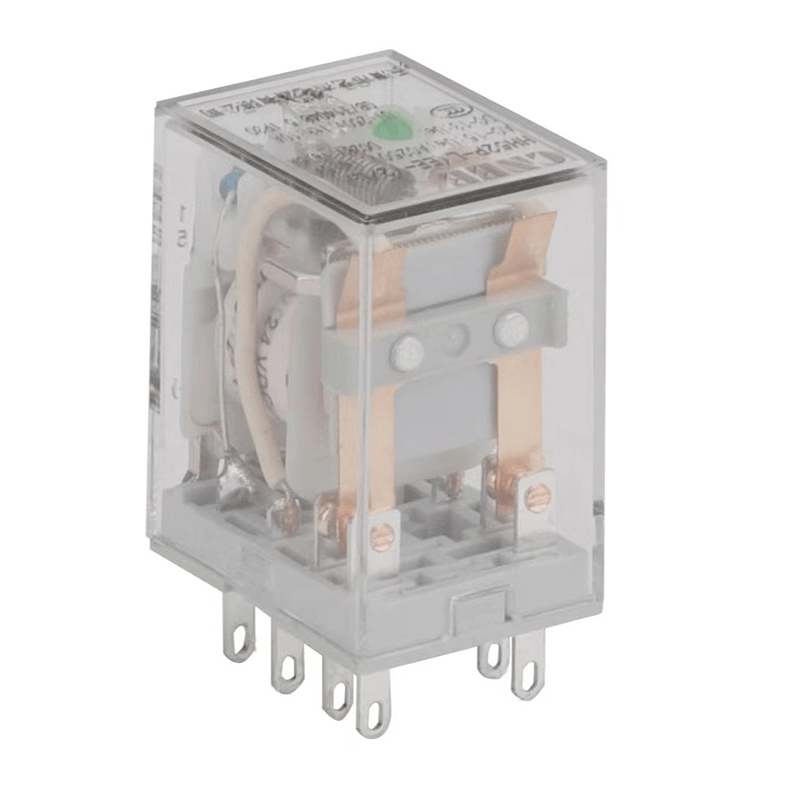

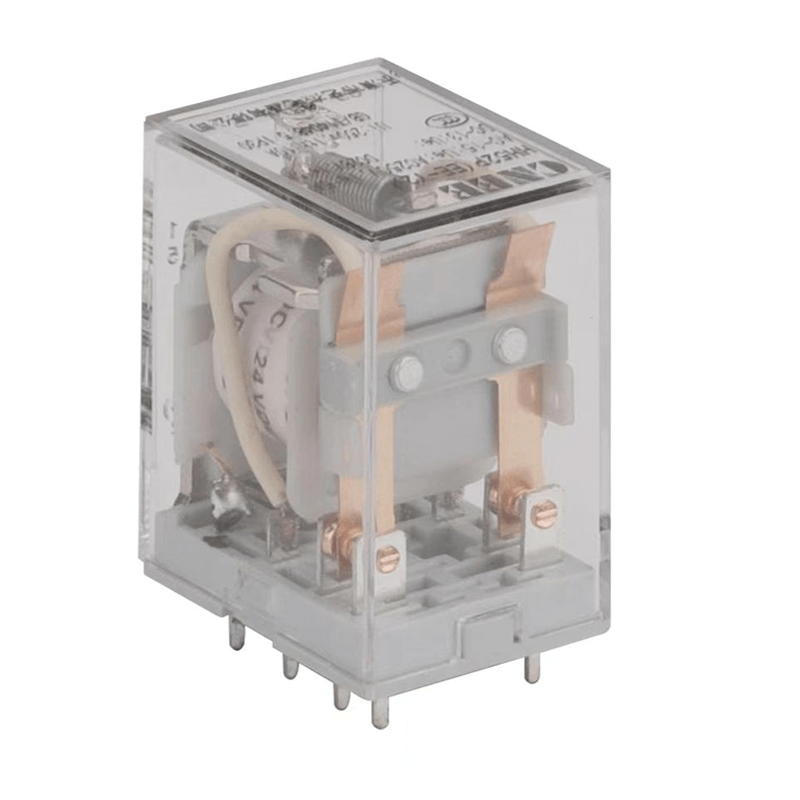

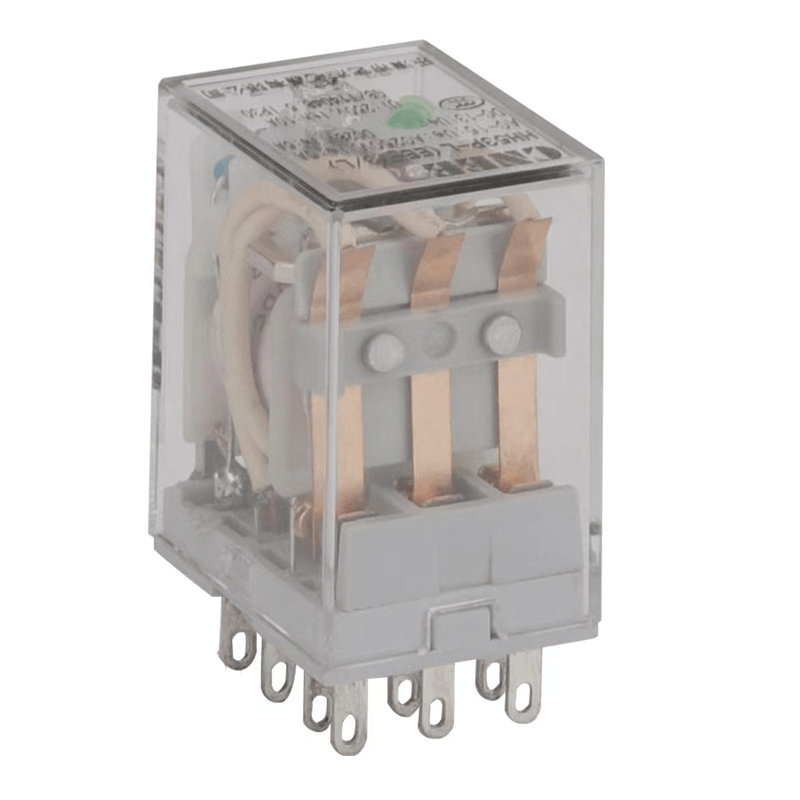

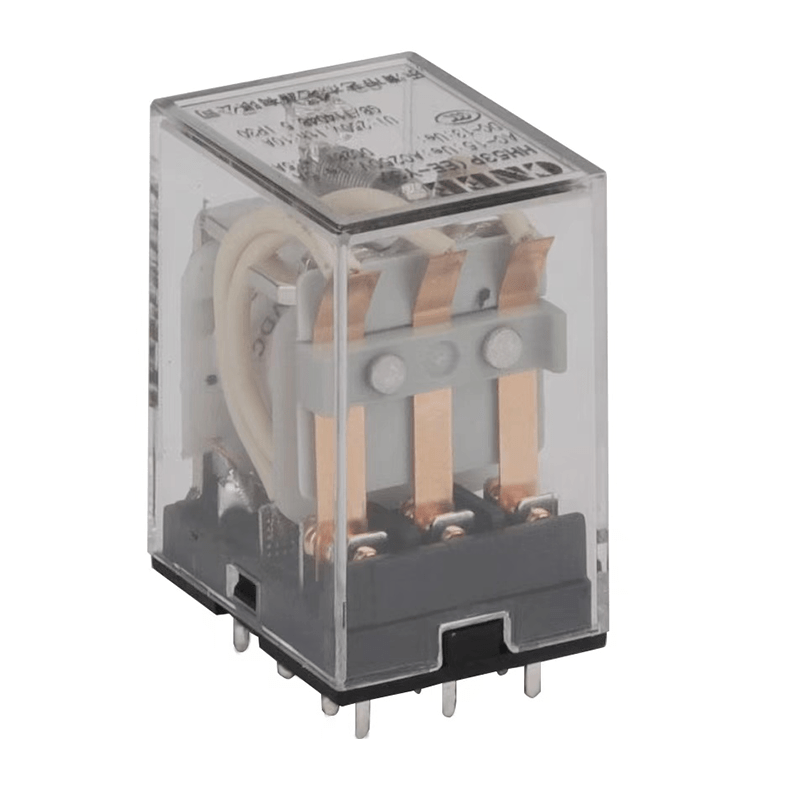

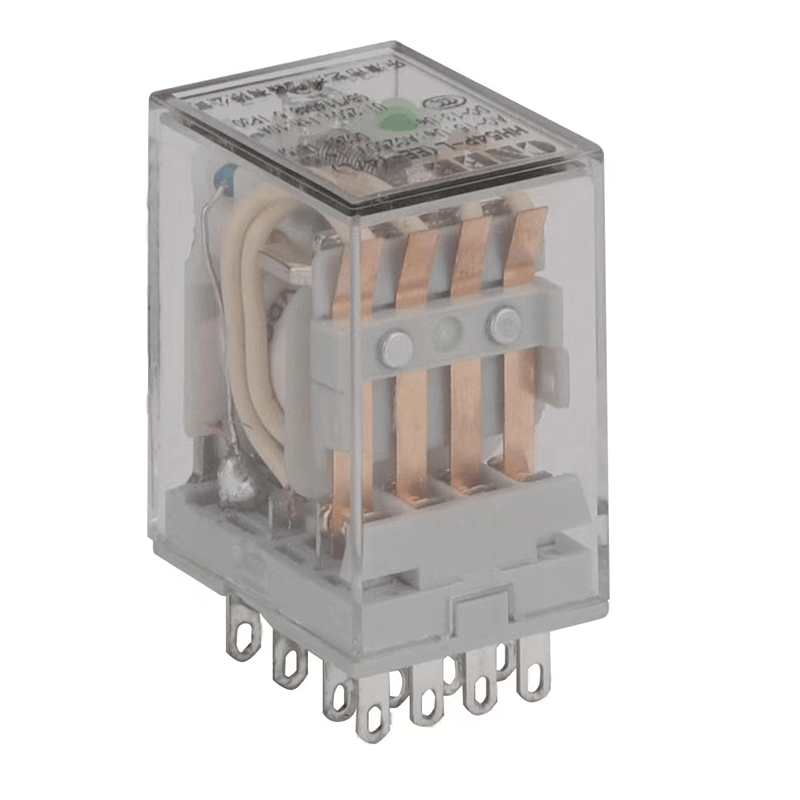

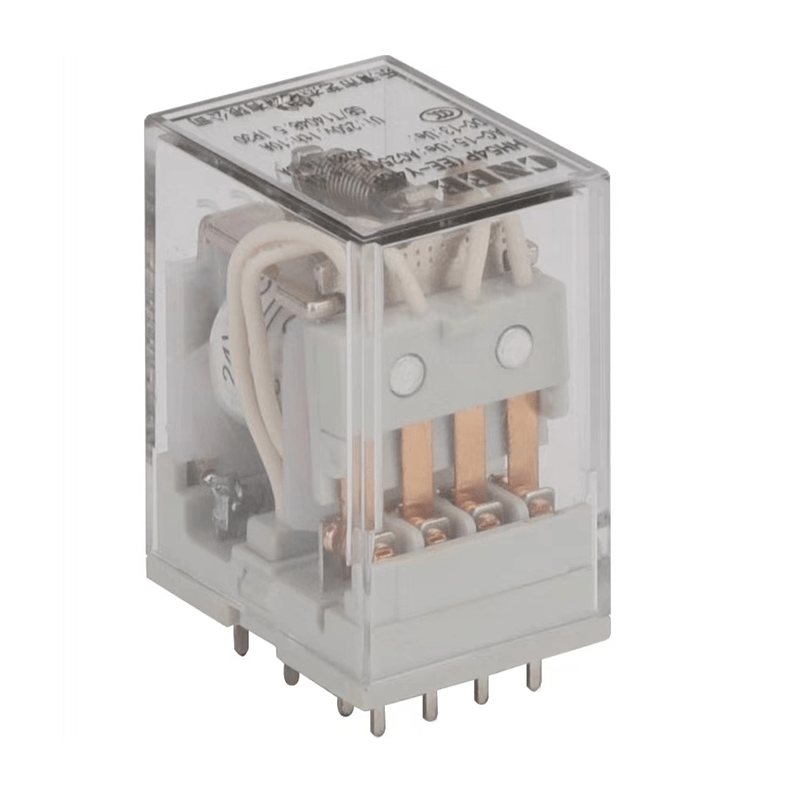

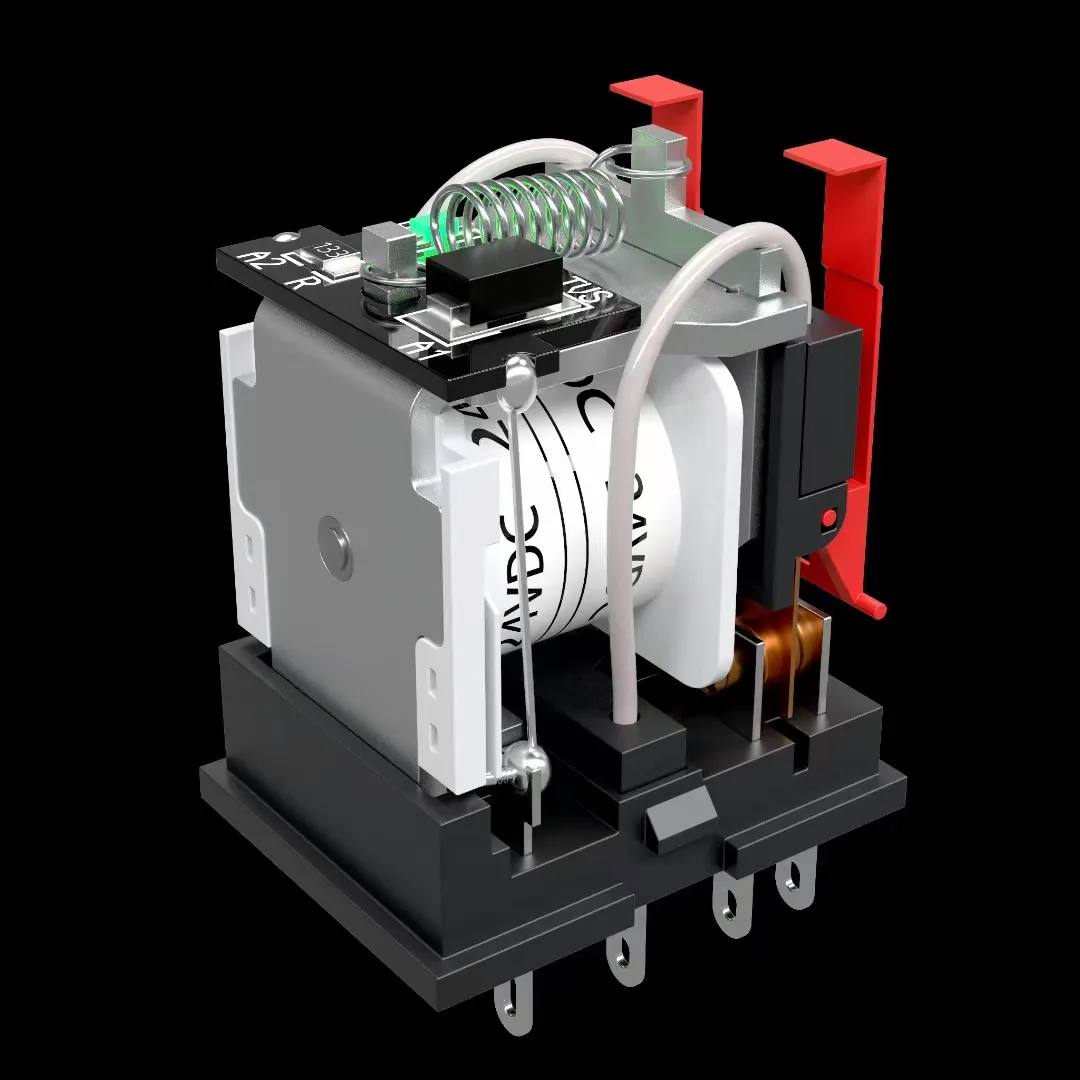

Most intermediate relays from hangwang consist of:

An electromagnetic coil powered by DC or AC

One or more switching contact groups (normally open or normally closed)

Optional features such as LED indicators, test buttons, and freewheeling diodes

Designs for plug-in or PCB pin-out connections

DIN-rail mountable sockets for simple installation and integration

Working Principle

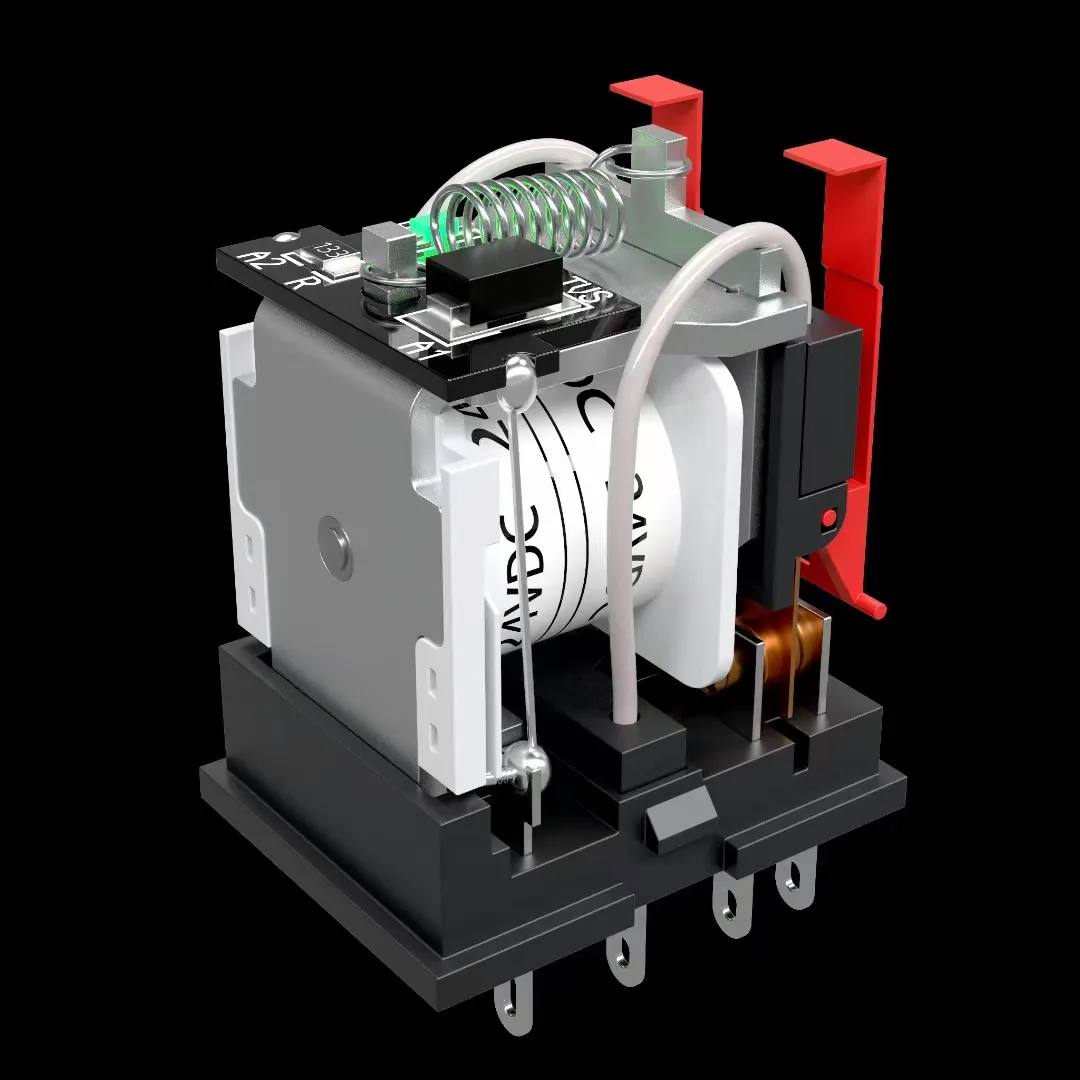

A relay uses a small electrical voltage to control a larger load. In a mechanical or magnetic relay with a power-switching contactor, the process works like this:

The logic circuit sends a control signal to the coil windings.

This creates a magnetic field that produces force.

The magnetic core strengthens this field enough to pull a spring-loaded armature.

When the armature moves, it closes a contact that activates a DC or AC contactor.

The contactor then completes the high-power circuit.

Depending on the control signal and contactor state, the connected device either starts or stops.

When the coil is turned off, the armature returns to its original position.

This causes opposite effects in the load and control circuits.

Types of Intermediate Relays

Intermediate relays come in two main types: electromechanical and solid state. The difference lies in their switching components—one uses moving parts, the other does not.

Electromagnetic Relays

These relays have mechanical parts, including a coil wrapped around a magnetic core, a movable armature, and contacts. When the coil is energized, it creates a magnetic field that pulls the armature, closing the circuit. Electromagnetic relays are simple and cost-effective, with higher contact capacity and the ability to handle higher voltages. However, they switch slowly, making them less suitable for high-frequency use.

Solid State Relays

Solid state relays use semiconductor devices and electronic circuits to control switching. They produce control pulses to open or close circuits and can operate multiple switches. While they are more expensive, they switch faster and have longer lifespans due to minimal wear. Their downside is they handle lower current and voltage levels, limiting their applications.

The role of the intermediate relay

An intermediate relay is a widely used electrical component designed to strengthen control signals, helping electrical equipment operate more reliably and steadily. It usually has two parts: a control circuit that receives the logic signal and an output circuit that manages the switching of electrical devices.

The main functions of an intermediate relay in electrical systems include:

Amplifying the control signal so it has enough power and voltage to handle high-power equipment.

Enabling complex control functions like logic decisions, counting, and timing by linking multiple relays together.

Protecting electrical devices during switching, ensuring safer and more stable operation.

Benefits of intermediate relays

Besides its main functions, an intermediate relay offers several advantages:

It improves system stability by reducing noise and interference in the control circuit.

It lowers equipment failure risk by preventing interference between the control and output circuits.

It saves costs by reducing the need for additional signal amplification circuits and wiring.

It makes maintenance easier by combining the control and output circuits for simpler troubleshooting.

How to Choose the Right Intermediate Relay for Your Application

When selecting an intermediate relay, consider these key factors related to the controlled circuit:

Ensure the coil power supply type and voltage match the control circuit. For example, a CNC machine powered by DC 24V requires a relay coil rated for 24V DC.

Choose the contact type (normally open or normally closed) and number based on the control circuit’s needs.

The rated voltage of the relay contacts must be equal to or higher than the controlled circuit’s voltage.

The contact current rating should meet or exceed the controlled circuit’s rated current. For inductive loads, use less than 50% of the relay’s rated current to prevent damage.

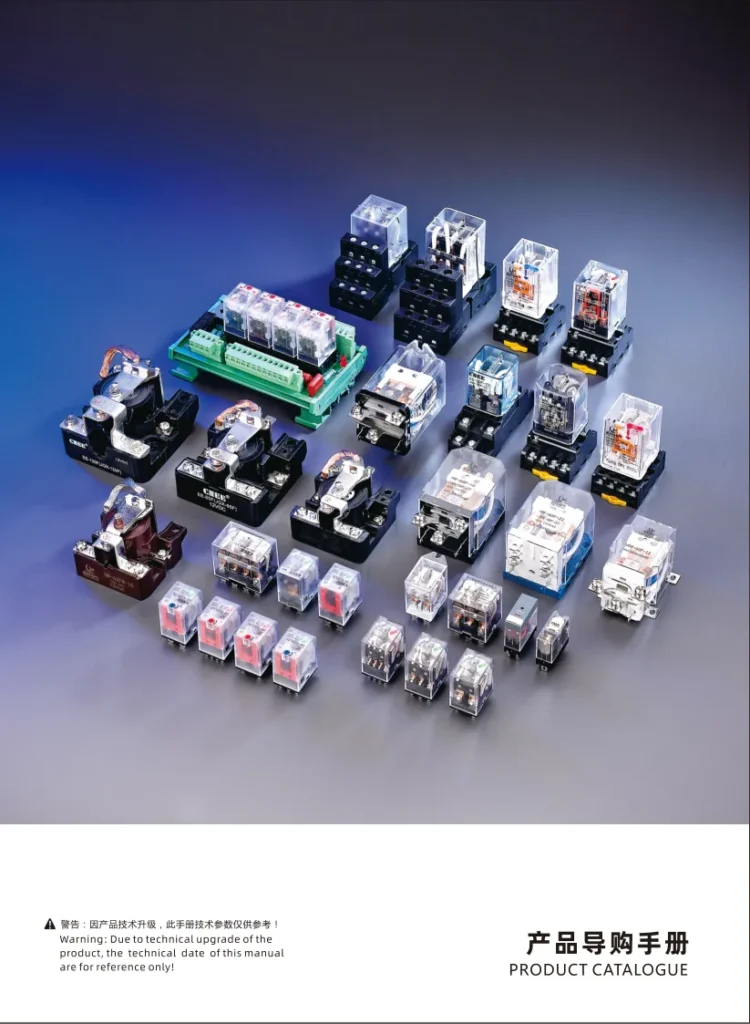

Why Choose Hangwang Intermediate Relays?

Certified Reliability with RoHS, CE, ISO9001, and ISO14001 standards

Customization options like LED indicators, gold-plated contacts, test buttons, and diodes

Compact designs ranging from slim 6mm models to 4-pole multi-contact relays

Flexible mounting options including snap-in sockets, rail, or screw terminals

One-stop sourcing with compatible sockets, modules, and accessories all in one system