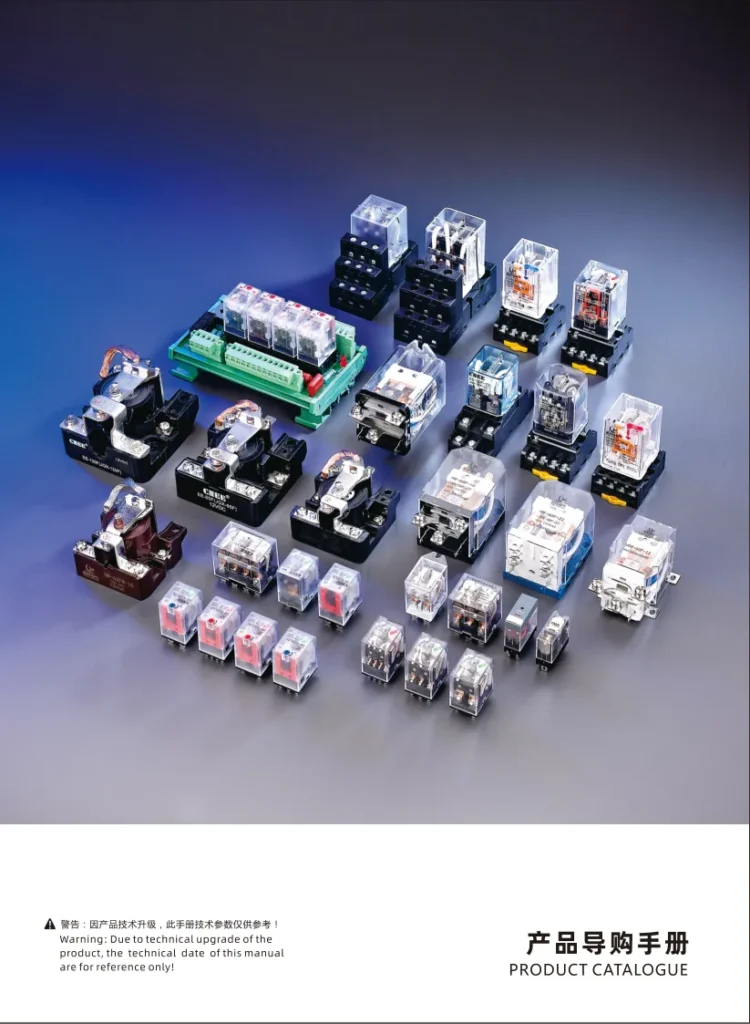

Industrial relays are designed for complex and changing industrial environments, with high durability and strong adaptability. They can withstand harsh conditions such as high temperature, high humidity, and vibration to ensure the stable operation of industrial automation equipment. Industrial relays are widely used in manufacturing, energy, transportation and other fields, and are an indispensable core component in industrial control systems.

Industrial relays are essential electromechanical or solid-state devices designed to control high-power electrical circuits using low-power signals. Widely used in industrial automation, manufacturing machinery, and control systems, these relays enable safe and efficient switching, isolation, and amplification of electrical loads. Compact yet robust, industrial relays support reliable control of motors, solenoids, valves, and other equipment under demanding conditions. They comply with international standards including CE, RoHS, UL, and TÜV, ensuring quality and safety in various industrial environments.

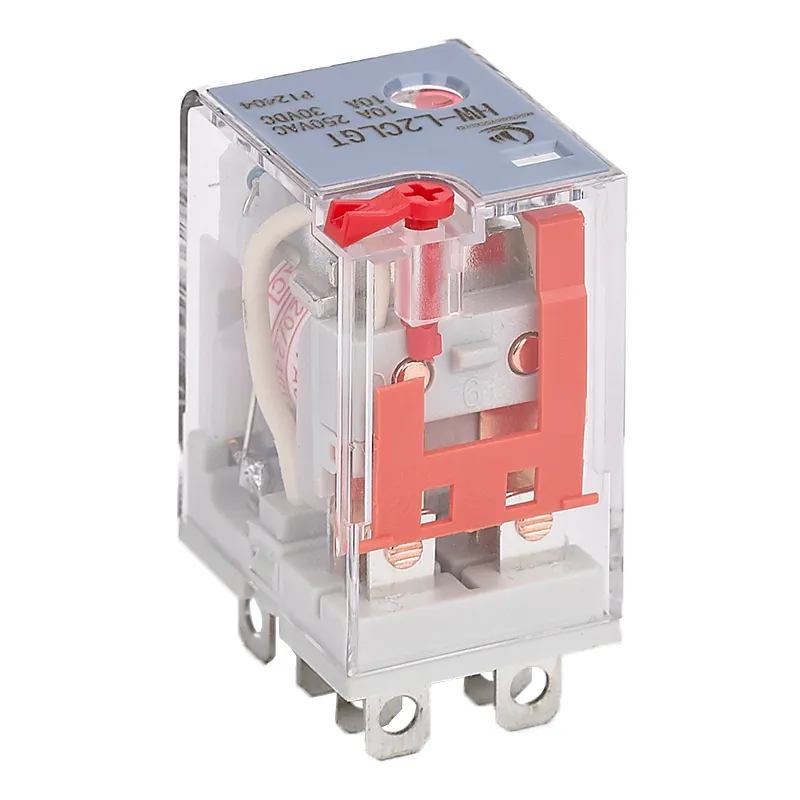

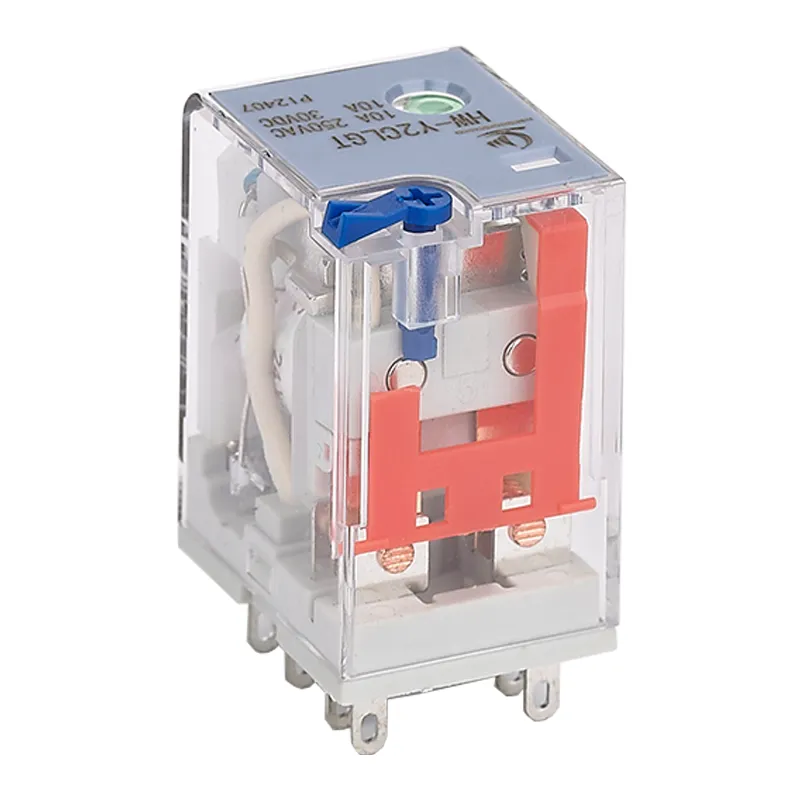

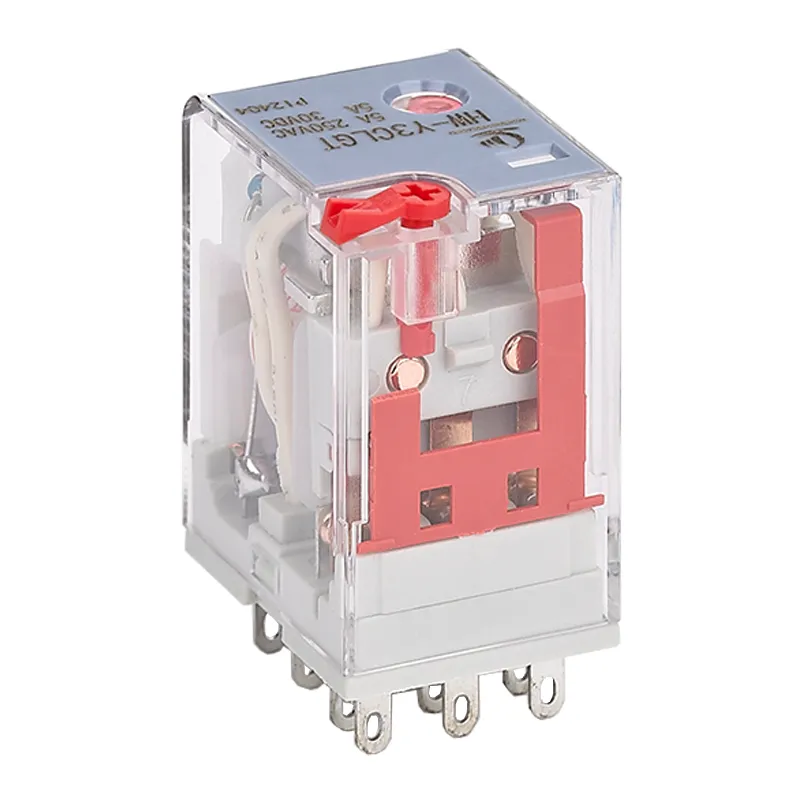

Main Features of Industrial Relays

- High current handling capability for controlling heavy industrial equipment and machinery

- Compact and slim design to save installation space

- LED status indicators, optional mechanical indicators, and test buttons for easy troubleshooting

- Different connection technologies: push-in with double chamber or screw connections

- Electrical isolation between control and power circuits for operator and device safety

- Versatile relay types including electromechanical, solid-state, latching, timing, and power relays

- Certifications and compliance: CE, RoHS, UL, TÜV standards for reliable operation

- Optional auxiliary modules for customized industrial applications

- Long electrical life with high DC breaking capacity and inductive load switching

- Fast response times suitable for automation and precise control.

Product Advantages

Industrial relays offer rapid response, accurate control, and automation capabilities that improve operational efficiency and safety. They isolate control circuits from high-power circuits to prevent damage and enhance system longevity. Relays amplify weak control signals to drive high-power devices and automate time-based or repetitive processes. Their ability to reduce energy consumption by avoiding prolonged operation of equipment not only lowers energy costs but also minimizes wear and tear. The combination of durability, ease of installation, and flexible designs makes industrial relays indispensable in modern automated systems.

Installation Steps and Maintenance

Installation Steps:

- Select the appropriate relay type and rating for the application based on load requirements.

- Mount the relay securely using provided brackets, sockets, or DIN rail mounts.

- Connect the control circuit wiring and power circuit according to the relay’s wiring diagram.

- Verify connection security, ensuring no loose terminals or short circuits.

- Test the relay operation by energizing the control input and observing the output switching.

Maintenance:

- Regularly inspect relays for signs of wear, corrosion, or contact degradation.

- Perform functional tests periodically to ensure reliable switching performance.

- Clean contacts and replace worn or damaged relays promptly to avoid failure.

- Use preventive maintenance schedules based on the operating environment and load cycles to extend relay service life.

- Consult manufacturer manuals for specific maintenance protocols and replace auxiliary modules as needed.

Detailed Applications of Industrial Relays

Industrial Automation: Control production lines, robotic systems, conveyors, and motor starters to ensure precise operation sequencing and safety interlocks.

Motor Control: Enable starting, stopping, and protection of motors in manufacturing and processing plants.

Power Monitoring: Use specialized relays for voltage and current monitoring in heavy-duty power systems.

Protective Circuits: Implement overcurrent, overload, and fault detection to safeguard equipment and personnel.

Home Appliances and Automotive: Manage electrical loads in appliances and vehicles, enhancing reliability and energy efficiency.

Time Control Functions: Achieve delay, periodic, or one-shot control for timed operations in industrial processes.