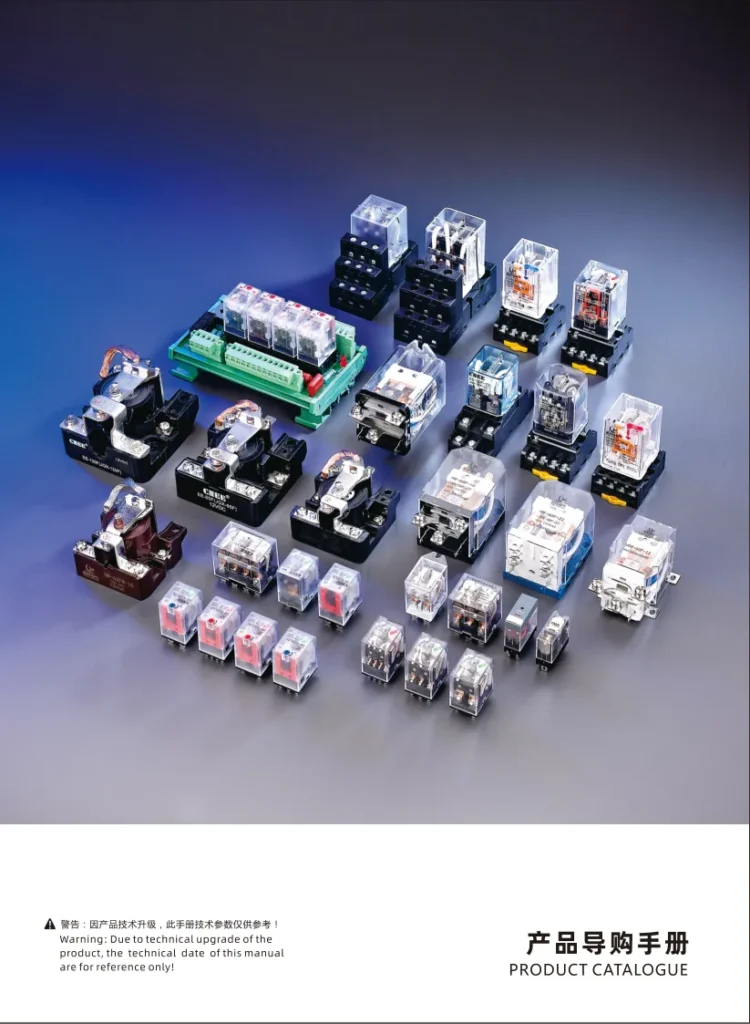

General purpose relays are standardized relay products suitable for a variety of applications, with wide compatibility and flexibility. These relays are usually designed to be modular and can be easily integrated into different types of control systems to meet diverse control needs. General purpose relays are widely used in industrial automation, household appliances, communication equipment and other fields, and are a common choice in various control applications.

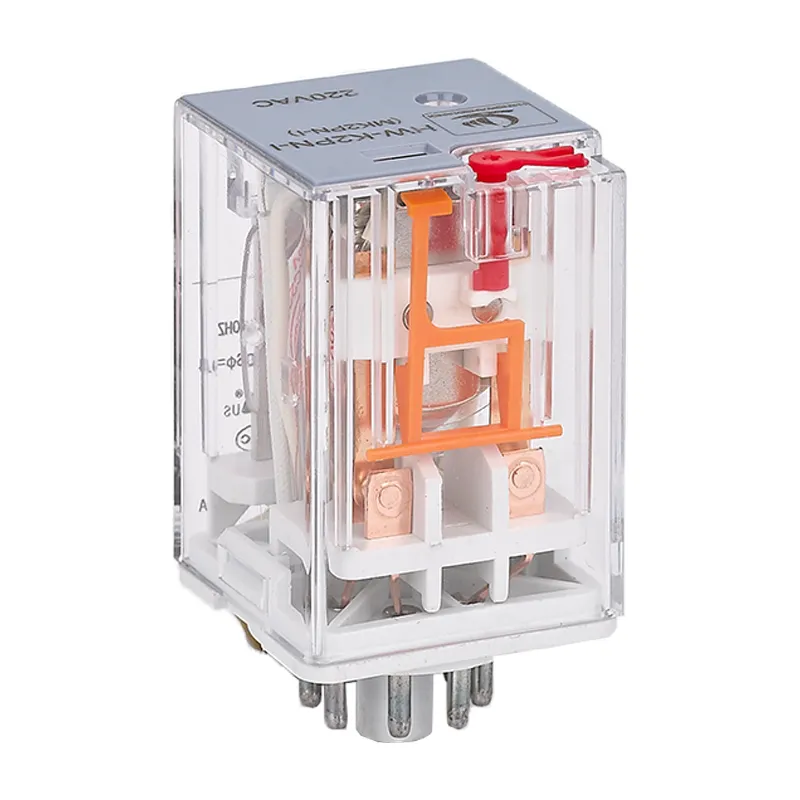

A General Purpose Relay is a versatile electrical switching device designed to control various external electrical loads by using a low-power input signal to switch high power circuits on or off. Unlike specialized relays, general purpose relays are adaptable across a broad spectrum of applications in industrial, commercial, and residential environments. They come in mechanical and solid-state types, often with transparent or rugged casing to protect internal components.

The device functions by using electromagnetic force or semiconductor components to switch contacts, enabling safe, efficient control of motors, lights, solenoids, and other loads. Their design allows for easy installation in control panels, automation systems, and electronic devices, making them a fundamental component in modern electrical control systems.

Main Features of General Purpose Relays

Wide Voltage and Current Ratings: Suitable for controlling a range of voltage levels from 5V to 250V AC/DC and current loads appropriate for various applications.

Multiple Contact Configurations: Available in normally open (NO), normally closed (NC), single-pole double-throw (SPDT), and double-pole double-throw (DPDT) options.

Mechanical and Solid-State Options: Mechanical relays use electromagnetic force while solid-state relays use semiconductor switching for quieter, faster, and longer-lasting operation.

Compact and Space-Saving Design: Small footprint suitable for mounting on DIN rails, PCBs, or plug-in sockets.

Built-in Indicators and Latching Levers: Some models feature mechanical indicators and latching levers for easy visual inspection and maintenance.

Robust Construction: Designed to operate reliably across wide temperature ranges and harsh industrial environments.

Advantages

- Versatility: Designed to work in numerous applications, replacing the need for multiple specialized relays.

Cost-Effective: Provides reliable switching at a low cost, reducing overall system expenses.

Easy Integration: Compatible with various control systems including PLCs, microcontrollers, and manual switches.

Long Service Life: Mechanical relays can offer over 100,000 operations, while solid-state variants provide silent switching and extended durability.

Energy Efficient: Low coil power consumption reduces overall energy use.

Safety and Isolation: Electrical isolation between the control and load circuits protects sensitive electronics.

Installation Steps and Maintenance Guidance

Installation:

Select the Correct Relay: Verify specifications to ensure compatibility with the coil voltage, load current, and contact type needed.

Prepare Wiring: Strip wires sufficiently and use appropriate terminals; refer to wiring diagrams for accurate connections.

Mount the Relay: Fix the relay socket on a DIN rail, panel, or PCB as applicable. Insert the relay securely into the socket.

Connect Control and Load Circuits: Attach input control wires to coil terminals; connect load wires to relay contacts following the circuit schematic.

Conduct Tests: Power on the circuit and use a multimeter to confirm proper relay coil energizing and contact switching.

Ensure Environment Suitability: Install in well-ventilated locations to avoid overheating and facilitate maintenance.

Maintenance:

Regularly inspect for physical damage, corrosion, and dust accumulation.

Clean external surfaces and terminals to maintain good electrical contact.

Test coil resistance and contact continuity periodically.

Replace relays showing signs of wear, overheating, or contact degradation.

Maintain appropriate ambient conditions to prolong relay life.

Applications of General Purpose Relays

Industrial Automation: Used extensively in control panels to operate motors, solenoids, conveyors, and automation machinery via relay sequences for seamless production control.

Household Appliances: Integral in appliances such as refrigerators, washing machines, and air conditioners for switching compressors, motors, and heating elements.

Automotive Systems: Controls lighting systems, fuel pumps, power windows, and other automotive electronics requiring reliable switching.

Telecommunications: Enables power distribution, signal routing, and protection circuits in communication infrastructure due to fast and reliable switching.

Building Automation: Controls lighting, HVAC, water treatment, and security systems to enhance energy efficiency and occupant comfort.

Renewable Energy: Manages power distribution and load regulation in solar panels and other renewable systems to optimize energy use.

Medical Equipment: Used in precision instruments and diagnostic devices requiring critical and reliable control mechanisms.