Relays utilize different types of contacts to control circuits based on specific conditions. The main contact types include Conversion Type, Normally-ON Type, and Normally-OFF Type. Here’s a detailed explanation of each:

Description of contact forms:

| Type | Default State | Energized State | Relay contact structure |

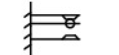

| Conversion Type | C to NC connected | C switches to NO |  |

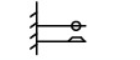

| Normally-ON Type | Open (disconnected) | Closed (connected) |  |

| Normally-OFF Type | Closed (connected) | Open (disconnected) |  |

Conversion Type (Changeover Contact, SPDT)

Conversion Type, also known as a changeover contact or Single Pole Double Throw (SPDT) contact, can function as either a Normally-ON or Normally-OFF contact, depending on the wiring.

- Structure:

- Composed of three terminals: Common (C), Normally Closed (NC), and Normally Open (NO).

- In the default state (relay coil unpowered), the contact connects C to NC.

- When the relay coil is powered, the contact switches to connect C to NO.

- Working Principle:

- Default (unpowered): The contact bridges C and NC.

- Powered: The contact switches to bridge C and NO.

- Applications:

- Useful for selecting between two circuits or toggling between two conditions.

- Common in circuit switching, signal routing, and power management applications.

Normally-ON Type (NO Contact)

The Normally-ON Type contact, also called Normally Open (NO), is open in its default state and closes only when the relay coil is energized.

- Structure:

- Comprises two terminals that remain disconnected in the unpowered state.

- Working Principle:

- Default (unpowered): The contact remains open; the circuit is incomplete.

- Powered: The relay coil creates a magnetic field that closes the contact, completing the circuit.

- Applications:

- Used in systems where the circuit should only be powered under specific conditions.

- Common in motor starters, lighting control, and load activation when a triggering condition is met.

Normally-OFF Type (NC Contact)

The Normally-OFF Type contact, also called Normally Closed (NC), is closed in its default state and opens when the relay coil is energized.

- Structure:

- Comprises two terminals that remain connected in the unpowered state.

- Working Principle:

- Default (unpowered): The contact remains closed; the circuit is complete.

- Powered: The relay coil energizes, opening the contact and breaking the circuit.

- Applications:

- Ideal for systems where continuity is required under normal conditions and should only break under specific conditions.

- Frequently used in safety circuits, alarms, and fault detection systems.

Materials Used in Relay Contacts

Relay contacts are critical components, and their material significantly impacts performance, durability, and suitability for specific applications. Below are the commonly used materials and their characteristics:

| Material | Properties | Limitations | Applications |

| Silver (Ag) | Excellent electrical conductivity Low contact resistance Good thermal conductivity | Oxidizes in humid/sulfur environments Oxide remains conductive | Low-voltage, high-current applications (e.g., power relays) |

| Silver Alloys | Enhanced strength Improved arc resistance Better wear resistance | Costlier than pure silver | High-power and high-frequency relays |

| Copper (Cu) | High electrical conductivity Affordable | Susceptible to oxidation Requires coatings | Rarely used alone; typically as base material |

| Gold (Au) | Combines gold’s anti-corrosion with base metal’s strength Cost-effective | Poor wear resistance High cost | Low-voltage, low-current applications (e.g., signal relays) |

| Gold-Plated | High corrosion resistance Performs well at high temperatures | Limited durability for high currents | Signal relays, low-power circuits |

| Platinum (Pt) | Extremely high melting point Superior arc resistance | – Very expensive | Specialized harsh environments |

| Tungsten (W) | High electrical conductivity Affordable | High contact resistance Brittle, less conductive | High-voltage, high-current relays |

Material Selection Considerations

- Electrical Current: Higher currents often require silver or silver alloys.

- Voltage: High-voltage relays benefit from materials with strong arc resistance (e.g., tungsten or silver alloys).

- Environment: Corrosive or humid environments may require gold or gold-plated contacts.

- Switching Frequency: Frequent switching demands materials with good wear resistance, such as silver tin oxide.