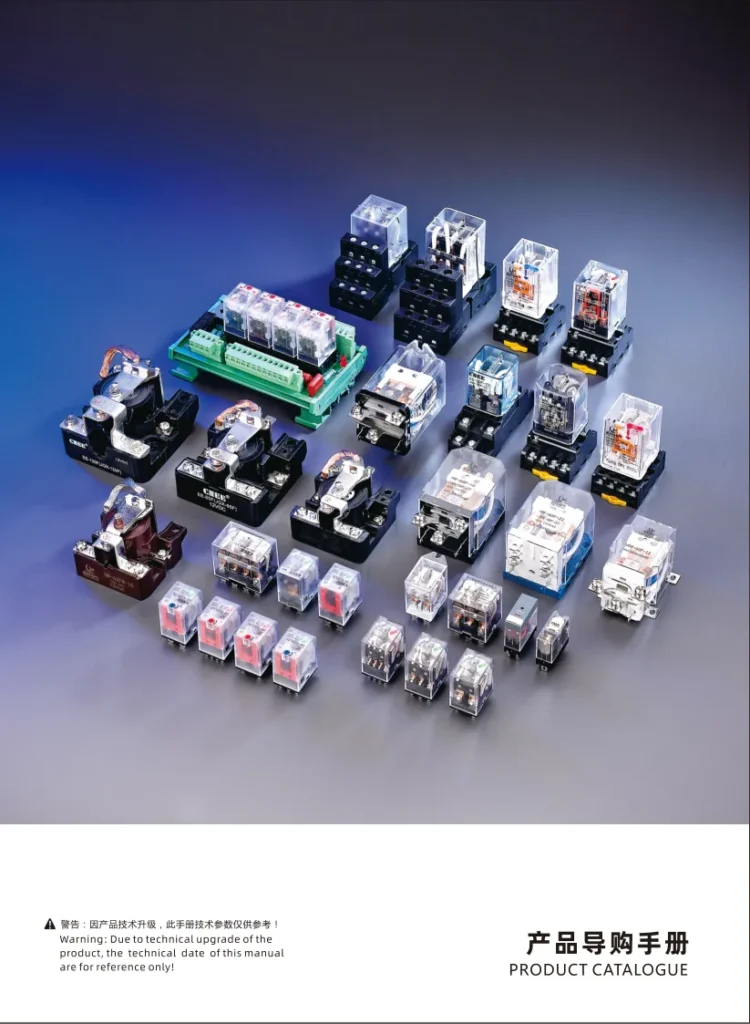

Uses of electromagnetic relay

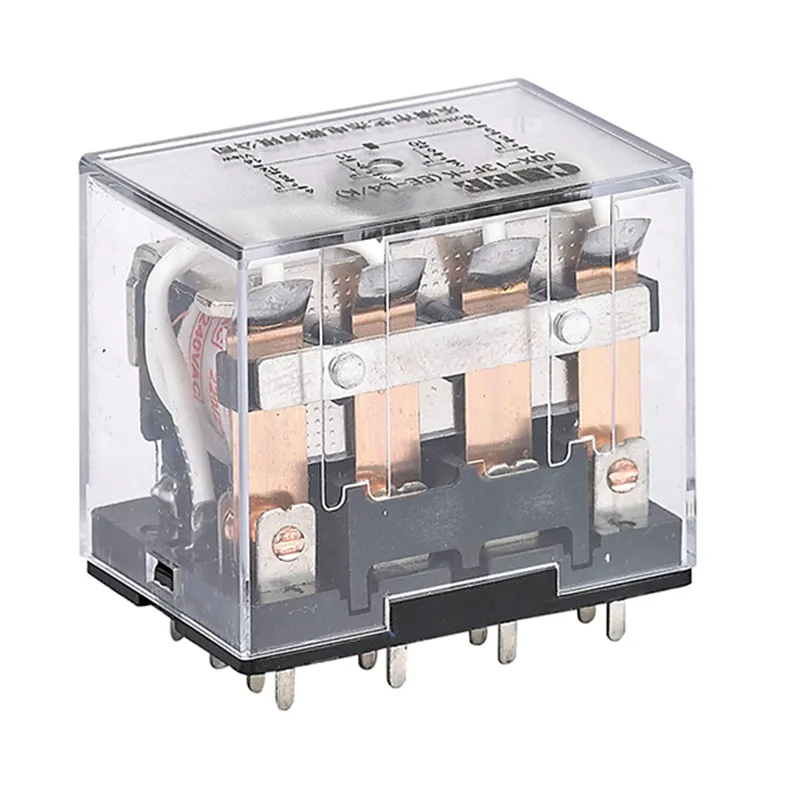

HW Electromagnetic Relay-L4C-P are a key control element that is widely used in various fields, using the principle of electromagnetic induction to achieve circuit on-off control.

Industrial applications: In industrial automation, electromagnetic relays are used to control the start and stop of large mechanical equipment, such as motors, pumps, and compressors. These devices usually require a large starting current, and relays can control large currents with small currents to achieve safe operation.

Household appliances: In household appliances, electromagnetic relays are used to control the operation of equipment such as air conditioners, washing machines, and refrigerators. Through relays, different working modes can be switched, such as the cooling and heating modes of air conditioners.

Automotive field: In automobiles, relays are used to control equipment such as starters, generator isolation, lights, and horns. Through relays, stable control of these equipment can be achieved to ensure the normal operation of the vehicle.

Communication system: In telephone exchanges and network equipment, relays are used for signal switching and line protection to ensure the reliability and stability of communication systems.

Main technical parameters

Choosing a suitable electromagnetic relay requires understanding its technical parameters, which directly affect its performance and applicable occasions.

Rated working voltage/current: This refers to the input voltage or current required by the relay coil for normal operation. When selecting, make sure to match the power supply conditions in the actual application.

DC resistance: The DC resistance value of the coil is an important indicator for judging the state of the coil. Too high or too low resistance may indicate that the coil is faulty.

Pull-in/release current: The pull-in current refers to the minimum coil current required to close the relay contacts, while the release current refers to the maximum coil current for the contacts to open. These two parameters determine the responsiveness of the relay under different load conditions.

Contact load: The contact load refers to the maximum switching capacity that the contacts can withstand, including the maximum allowed voltage and current. When selecting, it is necessary to match according to the load characteristics to avoid burning or welding of the contacts.

How to test the contact resistance of an electromagnetic relay

Testing the contact resistance can help determine whether the relay is working properly and is an indispensable step in the maintenance process.

- Measure with a multimeter: Set the multimeter to the ohm position and measure the resistance between the normally closed contact and the normally open contact respectively. When not powered, the normally closed contact should show close to 0Ω, while the normally open contact should show infinity. When the rated working conditions are applied, the normally open contact should show a low resistance value, while the normally closed contact should show a high resistance value.

- Coil test: Measure the DC resistance across the coil to confirm whether it is normal. Under normal circumstances, the coil should have a resistance value within a certain range. If the measured value deviates from the standard range, it may indicate that the coil is damaged or short-circuited.

- Dynamic test: You can judge whether its performance meets the requirements by applying the rated working conditions to the coil and observing the contact action. Ensure safe operation during the test to prevent accidental injury.

What are the safety precautions for electromagnetic relay?

To ensure safe use and extend the life of the equipment, the following precautions should be taken:

Apply rated operating conditions: Always use rated operating conditions that meet the requirements of the specification to avoid overheating or damage to the coil due to excessively high or low input.

Regular maintenance and inspection: Regularly inspect and clean the relay, especially the contact part, to prevent poor contact due to dust, oil or oxidation, which will affect performance.

Environmental condition management: Avoid long-term use in high humidity, high temperature or corrosive environments to prevent aging of insulating materials and performance degradation. If necessary, sealed relays can be used to improve environmental adaptability.

Anti-vibration measures: Ensure that the installation position is stable and take appropriate anti-vibration measures to avoid loosening or damage to the internal structure due to vibration. During transportation, care should also be taken to avoid severe collisions.

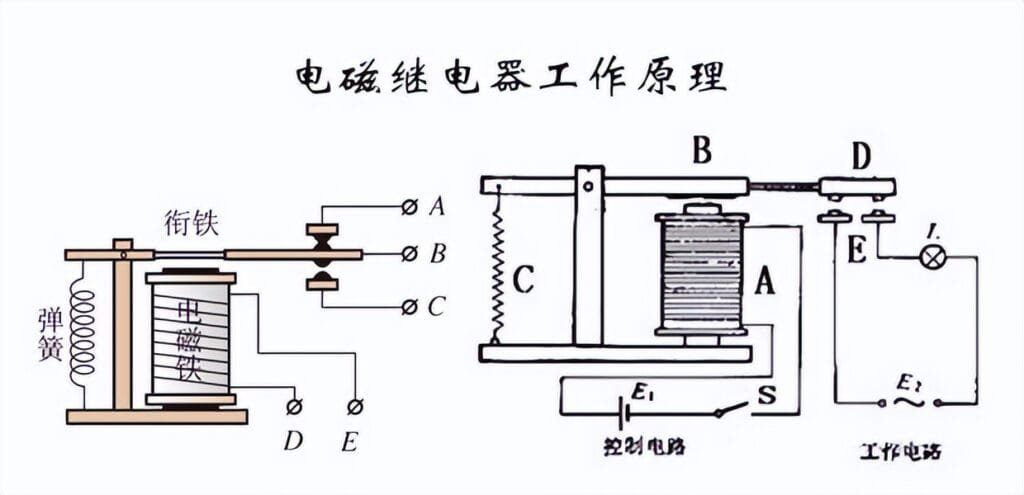

Working principle structure diagram